A quality visual inspection of welds is not limited to a mere glance at the weld seam. Visual inspection must be carried out according to standardized requirements that define very precisely all the practical aspects of weld seam quality control.

- No products in the cart.

Specifications for Visual Inspection of Weld Seams

The international standard that provides guidelines for the execution of quality visual inspection of weld seams is the EN ISO 17637 standard.

Some specifications include:

The accessibility to the weld seam must be sufficient for the eye to be located less than 600 mm from the surface to be observed and at an angle not less than 30 degrees.

The lighting of the surface:

- Type of light: white

- Minimum : 350 lx

- Recommended: 500 lx

The weld quality control report must include the following information:

- the name of the manufacturer of the component

- the name of the control organization, if different from the manufacturer’s name

- the identification of the controlled object

- the material

- the type of assembly

- the material thickness

- the welding process

- the acceptance criteria

- welding imperfection exceeding the acceptance criteria and their position

- the extent of weld inspection illustrated where appropriate by drawings

- the welding control devices used

- the result of the control in relation to the acceptance criteria

- the name of the inspector and the date of the weld quality control

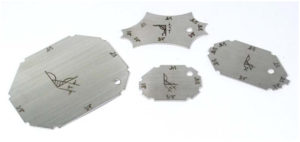

The EN ISO 17637 standard (2003 edition) cites as information examples of classic measurement tools for weld seam control. BEWARE that all tools available on the market from 2003 to today are MEASURING tools, therefore it is very important to keep in mind that it is impossible to immediately qualify a defect as acceptable or not acceptable.

Measurement tools are divided into two types:

1. Vernier-type measuring tools

2. Gauge-type measuring tools

Classic measuring tools make visual inspection of welds very difficult.

User testimonials

The VT® gauge principle is GO or NOGO. Measurements, calculations, and manipulation of standards are not involved.